Manroland has recently celebrated a “double joy” by winning both an authoritative certification in the cigarette pack industry and in-depth recognition from enterprises. These are not just two heavyweight honors, but also the best proof of “strong strength + excellent service” in the printing equipment field.

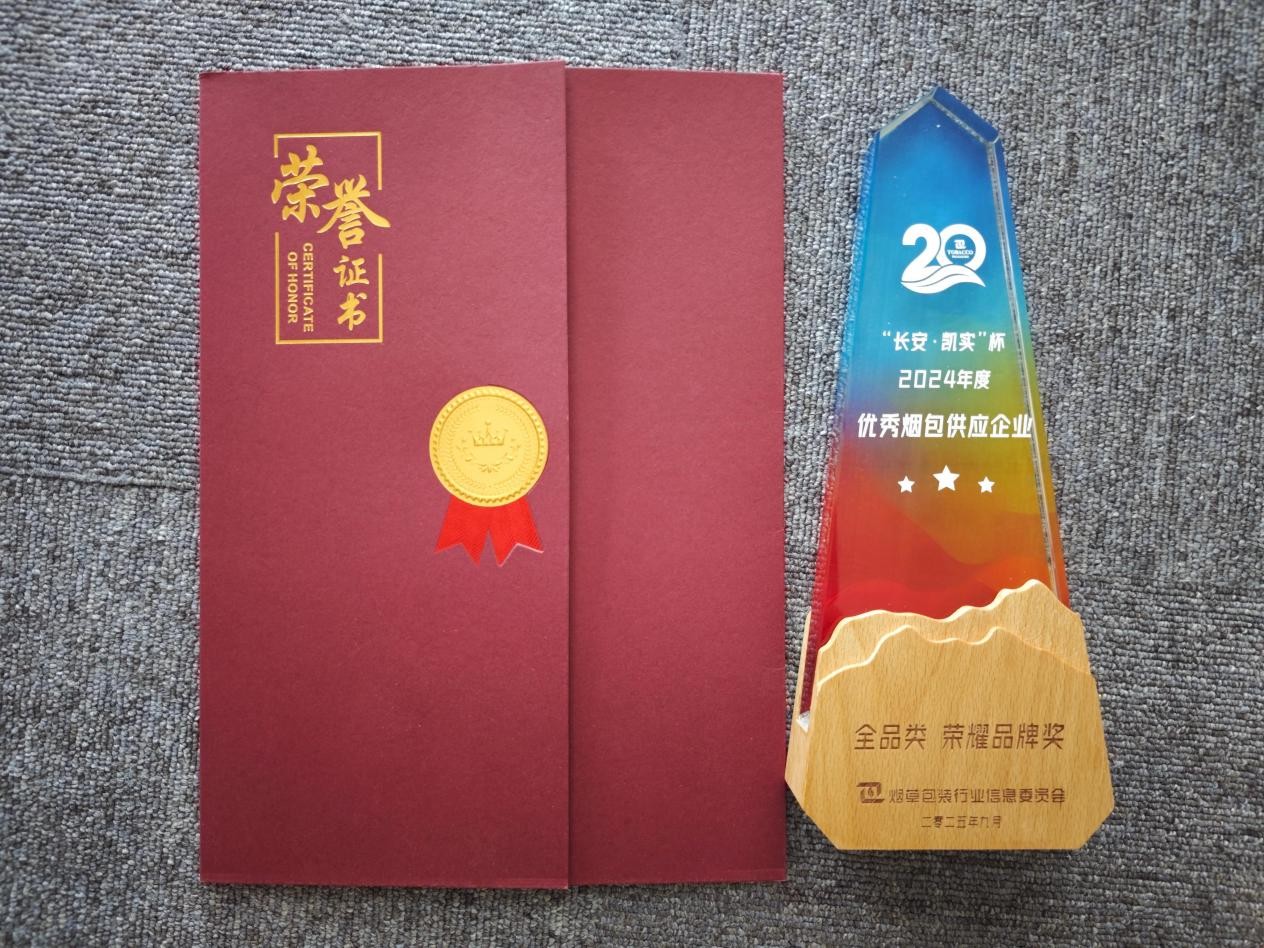

“Honorable Brand Award” for Cigarette Pack Suppliers: Expanding High-end Market with Strong Strength

Cigarette pack printing has always been the top arena for industry technical standards. It not only requires the realization of delicate pattern reproduction, but also needs to meet the production standards of cost reduction and efficiency improvement.

Different from the single-process limitation of ordinary printing equipment, Manroland’s equipment has built a “full-process compatibility system”, which accurately meets the full-process needs of cigarette packs from basic printing to high-value-added processing.

Eco-friendly Process as Priority: In terms of green production, the equipment can flexibly switch between traditional UV and LED UV curing systems. Compared with traditional UV, the LED UV process reduces energy consumption by 40% and significantly lowers VOCs emissions.

Inline Efficiency Upgrade: The built-in inline coding system of the equipment can directly print cigarette pack traceability codes and batch information, eliminating the need for supplementary printing in subsequent processes. This shortens the production cycle and solves the efficiency loss problem of the traditional offline operation of “printing – coding”.

Anti-counterfeiting Process Implementation: To meet the core anti-counterfeiting needs of cigarette packs, the equipment supports inline production of cold stamping process, realizing the integrated processing of “cold stamping + QR code coding”. This not only avoids the overprinting deviation caused by switching between multiple devices (with precision controlled within ±0.1mm), but also improves the stability of anti-counterfeiting marks, supporting tobacco brands in their high-end anti-counterfeiting cigarette label orders.

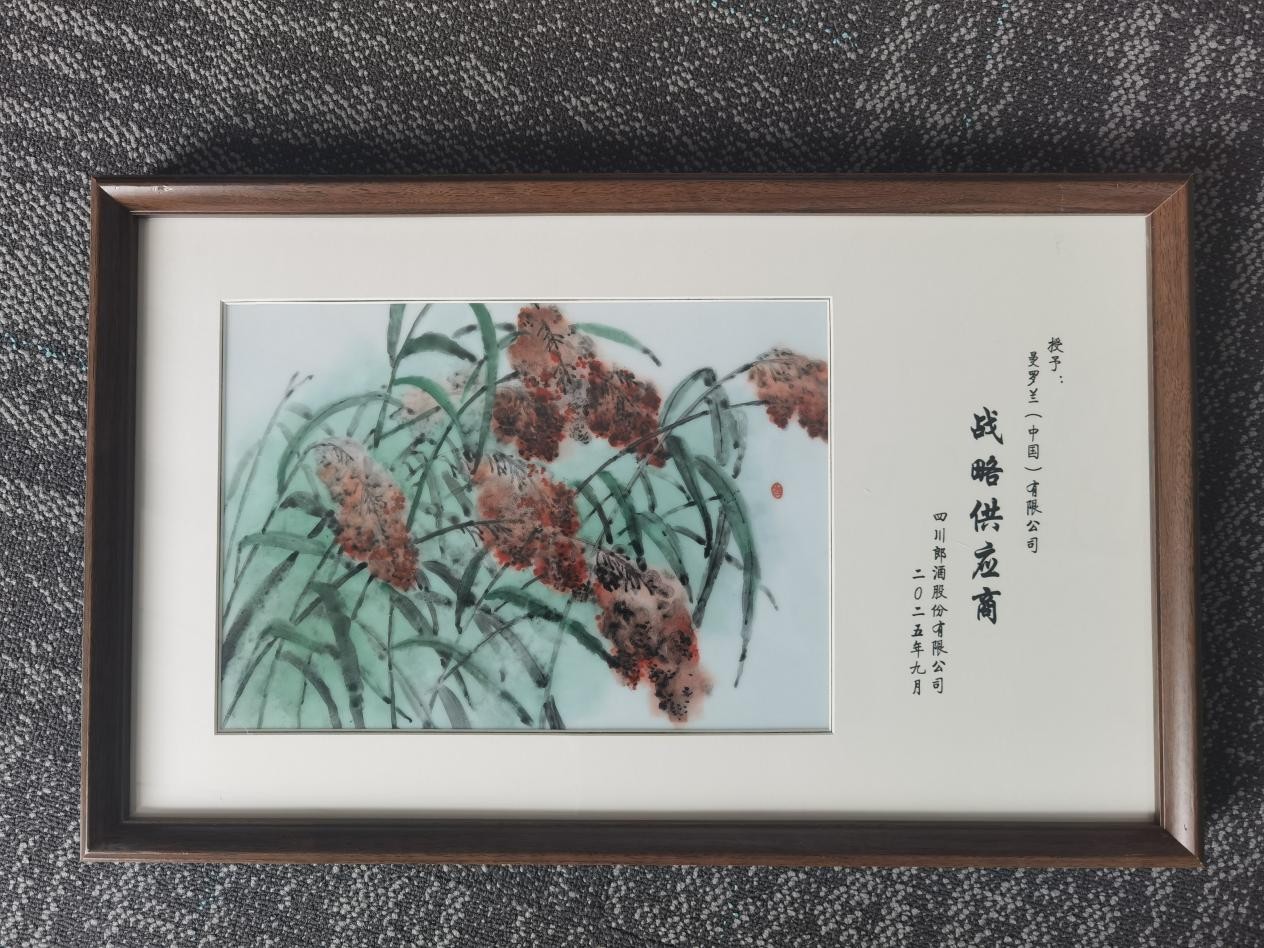

“Strategic Supplier” of Langjiu: From Equipment Provider to Value Co-Creation

If industry awards represent “collective recognition”, the “Strategic Supplier” title awarded by Langjiu is a “strong endorsement of in-depth trust” from a customer. As a leader in the Baijiu industry, Langjiu has extremely strict requirements for packaging color consistency and anti-counterfeiting precision. Manroland’s ability to enter its core supply chain lies in the dual breakthroughs of “customization + stability”.

To meet the packaging needs of high-end liquor series, Manroland’s printing press network management system and automatic ink supply control device ensure highly consistent visual effects of products from different batches. Relying on “PreServ360° Performance” comprehensive performance management, it provides 24-hour responsive operation and maintenance support, minimizing production downtime and ensuring stable packaging supply during peak seasons. The cooperation between the two parties has evolved from simple equipment supply to value co-creation with joint optimization.

Behind the Dual Awards: Manroland’s “Long-Termism” Code

From the “Honorable Brand” in the cigarette pack industry to the “Strategic Partner” of Langjiu, Manroland’s dual awards are no accident.

Against the backdrop of rising concentration and increasingly fierce competition in the printing equipment industry, Manroland has always adhered to the principle of “taking customer needs as the core”:

It develops customized solutions for different industries, enhancing flexible production capabilities in the packaging printing field and breaking through technical barriers in the special printing field.

It relies on technological innovation to solve industry pain points, simplifying operation processes with intelligent systems and reducing corporate compliance costs through green technologies.

It ensures in-depth cooperation with efficient services, maximizing equipment value through full-cycle operation and maintenance.

Today, the printing industry is moving toward a new stage of “intelligentization, greenization, and flexibility”. Manroland’s dual award honors are not only recognition of its past achievements, but also a starting point for the future.

About Manroland Sheetfed

Manroland Sheetfed GmbH is a leading German producer of sheetfed offset litho printing presses. Founded in 1871, the company is one of the oldest producers of printing presses in the world. Today the company has its own subsidiaries in over 40 countries and is a global watchword for supreme quality and reliability. Manroland Sheetfed GmbH was acquired by Langley Holdings plc in 2012.